Introduction

Supply Chains

In 2021, The Wall Street Journal polled economists on the potential threats to economic recovery from the Covid-19 recession. Around half of respondents cited supply-chain bottlenecks as the biggest threat to economic growth in the next 12 to 18 months, while nearly one-fifth pointed to labor shortages. They also expect supply-chain woes to weigh on the economy through much of next year. Some 45% estimate that it will take until the second half of 2022 for bottlenecks to have mostly receded, compared with two-fifths expecting major improvements before then.

Accidents

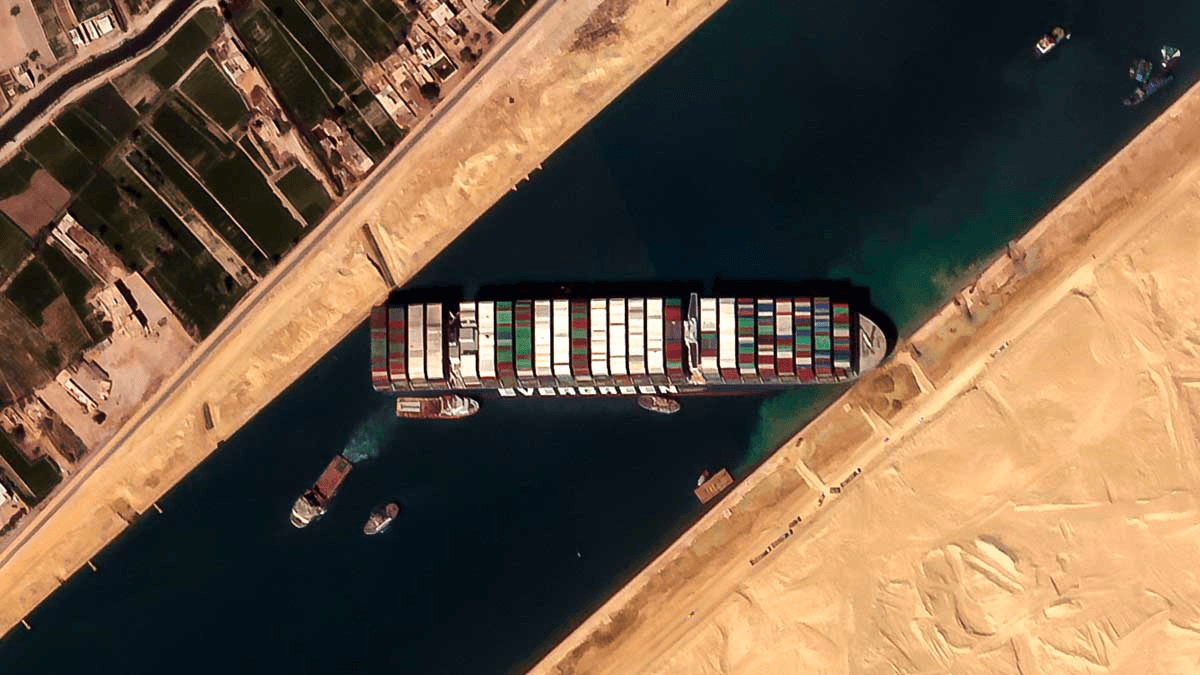

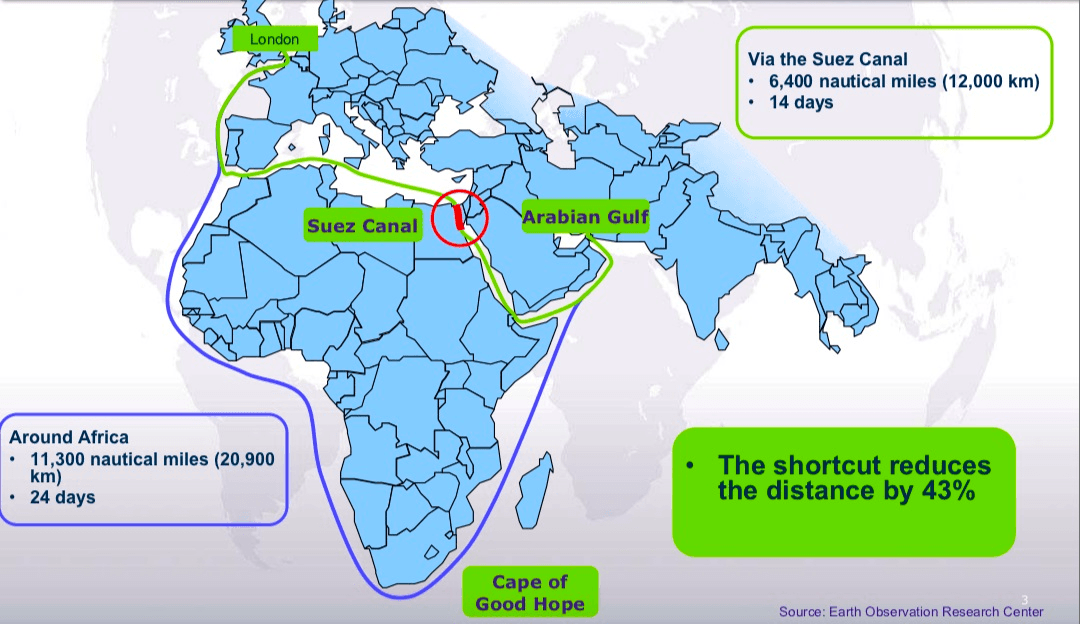

The Suez Canal is a waterway that connects the Mediterranean and the Red Sea. It is the busiest shipping passage in the world, and without it, ships would be forced to travel around the entire continent of Africa to make deliveries! In March of 2021, the Ever Given container ship got stuck in the Suez passage, preventing other ships from passing through the canal. Ships forced around the continent of Africa have cost businesses and manufacturers a total of $400 million for every hour the Ever Given remained stuck.

With 10% of the world’s shipping being prevented from reaching Europe, the $5.1 billion dollar-a-day disaster caused problems for retail, gas, and manufacturing industries. One UK company said it had 20 containers stranded on the Ever Given and were waiting on food products like coconut milk and syrups, spare parts for motors, and even forklift trucks. On top of monetary costs, the short-term emissions from forcing other container ships to take alternate routes have impacted local environments.

The blockage of the Suez Canal demonstrates how fragile the supply chain can be and how a small error can cause global economic disruption. Whether the disaster happened due to weather, a ship malfunction, or pilot error, the billions of dollars lost by businesses trying to recover from Covid-19 had significant impacts worldwide. (Demand Inflation)

Backups

With supply chain backlogs reportedly being the main threat to economic recovery, the inefficiencies in unloading cargo in Long Beach, California, present a significant problem. Thousands of containers were (and still are) stacked at the port, unable to be offloaded fast enough. At one point, more than 150 ships were parked off the coast, waiting for enough containers to be cleared for them to unload their shipments. Trucks were backed up in nearby residential neighborhoods causing days of traffic. Shipping backlogs such as this can cause several additional problems nationwide. Many containers hold the parts and raw materials that US factories need to domestically build their products, including automobiles, aircraft, and appliances.

The Biden administration allowed for extended hours of operation in the port complex to alleviate the container crisis. In addition, California Governor Gavin Newsome issued an executive order allowing containers to be stored in other state-owned parking lots.

Sources like the Commercial Carrier Journal have linked Covid-19 work requirements to the delays and staff shortages potentially causing the backlog; however, other sources indicate that a compounding factor of online purchases has resulted in more ships at the port. Another problem is the increased price of shipping containers due to a shortage. The shipping container problem is so dire that a single container costs over $33,000 in 2021 compared to $2000 in 2019. That's 16.5 times more expensive! Many of those upcharges are shifted to the price of consumer goods. (Cost-Push Inflation)

Classroom Content

Browse videos, podcasts, news and articles from around the web about this topic. All content is tagged by bias so you can find out how people are reacting across party lines.

Battle underway to unblock the Suez Canal as global trade is impacted

- Video •

- 2/26/2021

Suez Canal blockage: Captain of Ever Given not aiding probe; calamity's cost tops $1B

- Article •

- 3/1/2021

Ports of Los Angeles, Long Beach To Operate 24/7 To Ease Supply Chain Backup

- Video •

- 9/13/2021

Historic Backlog of Cargo Ships at the Port of Long Beach

- Video •

- 9/11/2021

Supply Chain Woes Lead to Highest-Ever Numbers of Ships Stuck Waiting at LA Ports

- Article •

- 9/19/2021